Projects

At RossTechnix, we pride ourselves on delivering innovative, reliable, and tailored solutions in automation and control systems. Our portfolio highlights a selection of projects that showcase our expertise in areas such as robotic integration, process optimisation, and bespoke machinery development.

Explore our portfolio to see how RossTechnix transforms complex challenges into streamlined, high-performing systems.

While we are excited to share our accomplishments, we also respect and prioritise the confidentiality of our clients. We adhere to strict non-disclosure agreements (NDAs) to safeguard sensitive information and ensure the integrity of every partnership. Below are a few projects we are able to share.

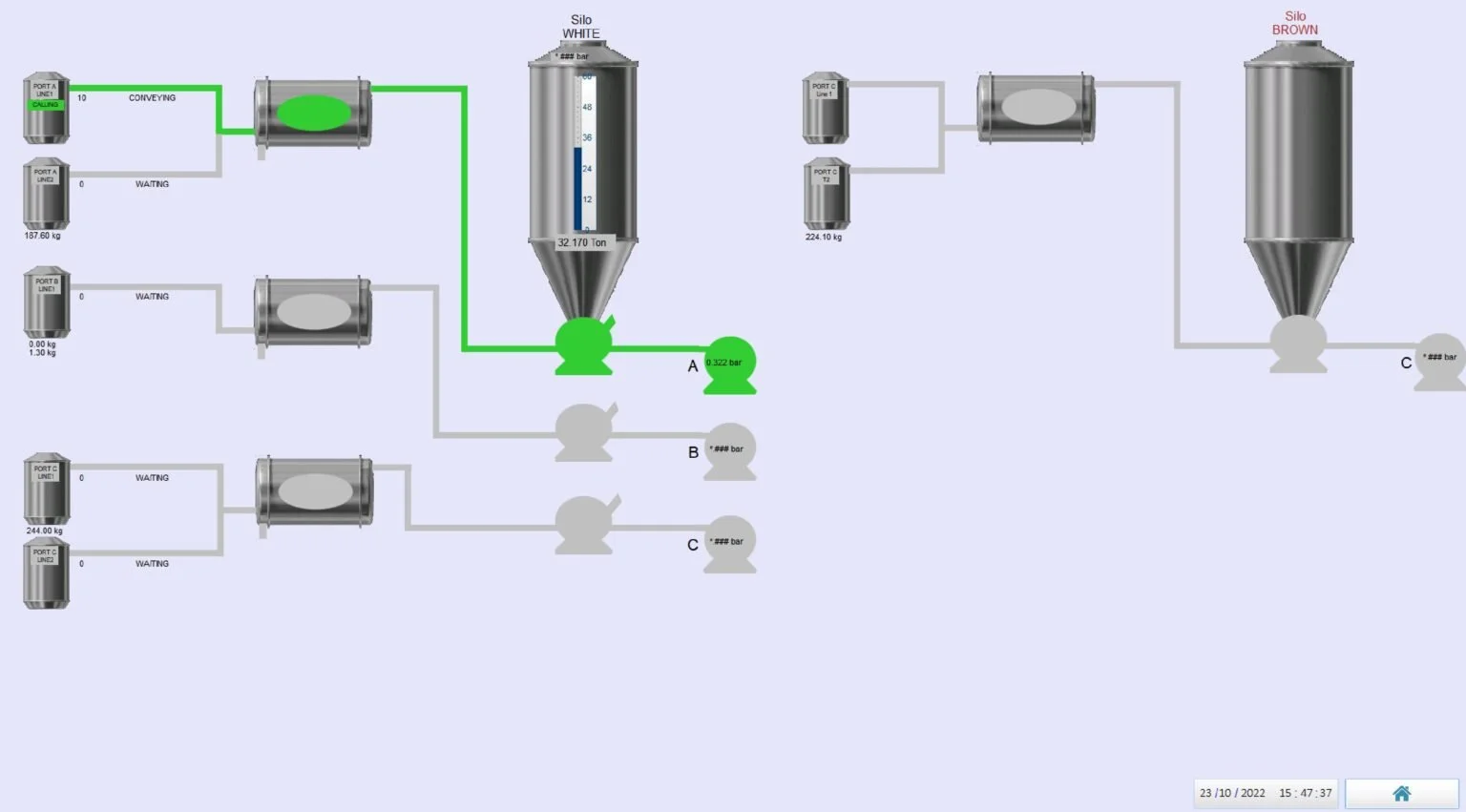

Mitsubishi PLC & HMI

Control for flour delivery system based on Mitsubishi PLC and HMI with separate remote access, enabling remote diagnostics with PLC/HMI code updates. Process data logging can also be achieved.

Mitsubishi PLC and Cartesian

Integration with Mitsubishi PLC and Cartesian robot for hot melt glue application.

Pick and Place Unit

Collaboration with Milton Keynes machine builder creating a Pick and Place unit, interfaced with customers test equipment. Objective to pick a part from the left hand tray, align the part, then carry out two tests. Depending on the result, either fully populate the right hand tray, or if tests failed place in reject bins for manual analysis.

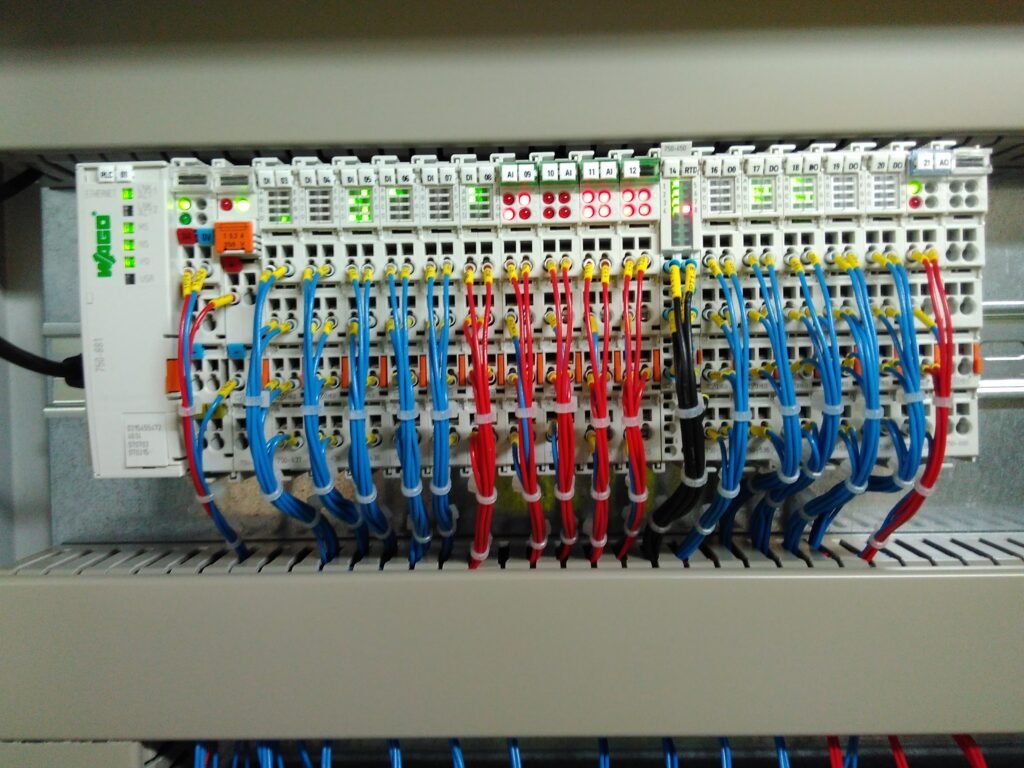

Wago PLC

Wago PLC programming with CoDeSys.

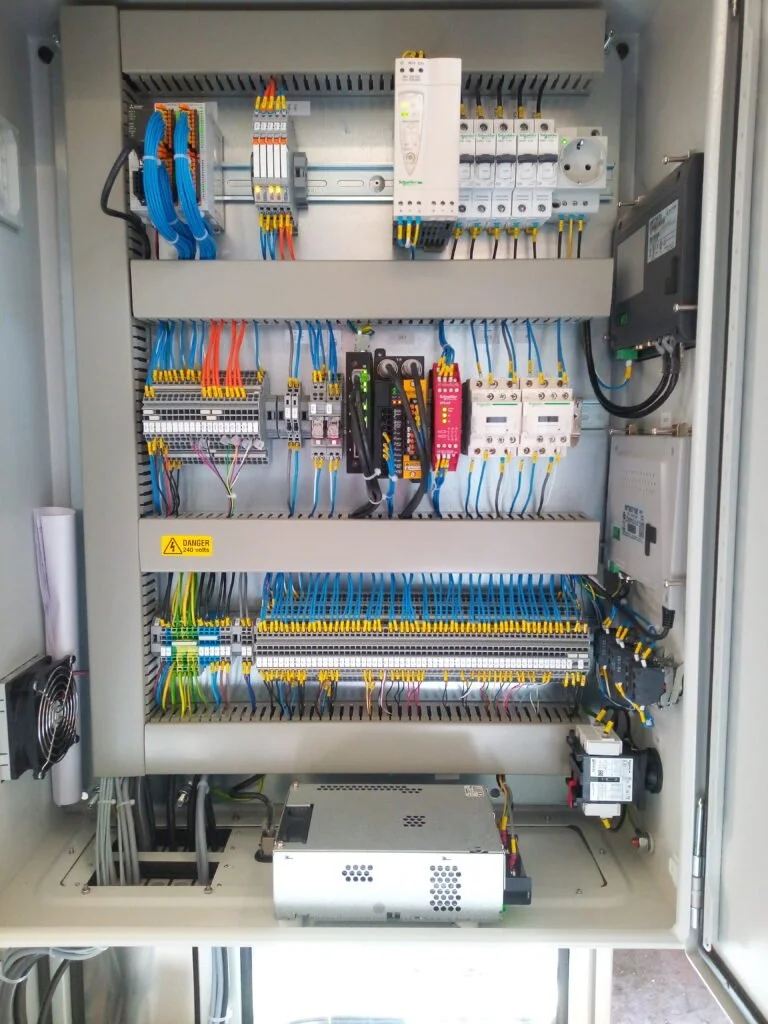

Panel Dressing and Wiring

Collaboration with Milton Keynes machine builder demonstrating control panel layout, dressing, populating and wiring.

Multi-Station Rotary Assembly, Welding & Inspection Machine

Collaboration with Milton Keynes machine builder, an eight station rotary assembly machine, controller programming and interfacing with Weintek HMI, Mitsubishi PLC, SMC linear drives, Sensopart Cameras, Mitsubishi SCARA robot and inhouse built components